Insight

How AI for Material Specification Analysis Reduces Procurement Errors

Jan 20, 2026

Procurement and material management is an endless cycle of 'comparison' and 'organization'.The key is to quickly structure information using consistent standards. By ensuring data consistency, ordering errors and quality risks can be dramatically reduced.This article, from a practical perspective, explains automated supplier evaluation, AI-driven quote comparison, and material spec document analysis.

Why Procurement & Material Management is Always Hectic

1-1. The Simultaneous Influx of Suppliers, Quotes, and Spec Documents

During RFI/RFQ/RFP stages, quotes and supporting documents arrive in myriad formats, units, and naming conventions. When mixed with technical specs like drawings, raw material standards, test reports, and certificates (CoC/CoA), it becomes incredibly difficult to grasp key differences through simple aggregation or sorting alone.

1-2. The Reality of Repetitive Comparison, Review, and Organization

It's rare for a comparison to be a one-off task. The vicious cycle of re-organizing from scratch restarts with every revised quote, alternative spec, delivery adjustment, or contractual clause change. While manual copy-pasting in Excel might seem fast, it creates hidden errors such as version conflicts, broken cell links, and overlooked unit conversions.

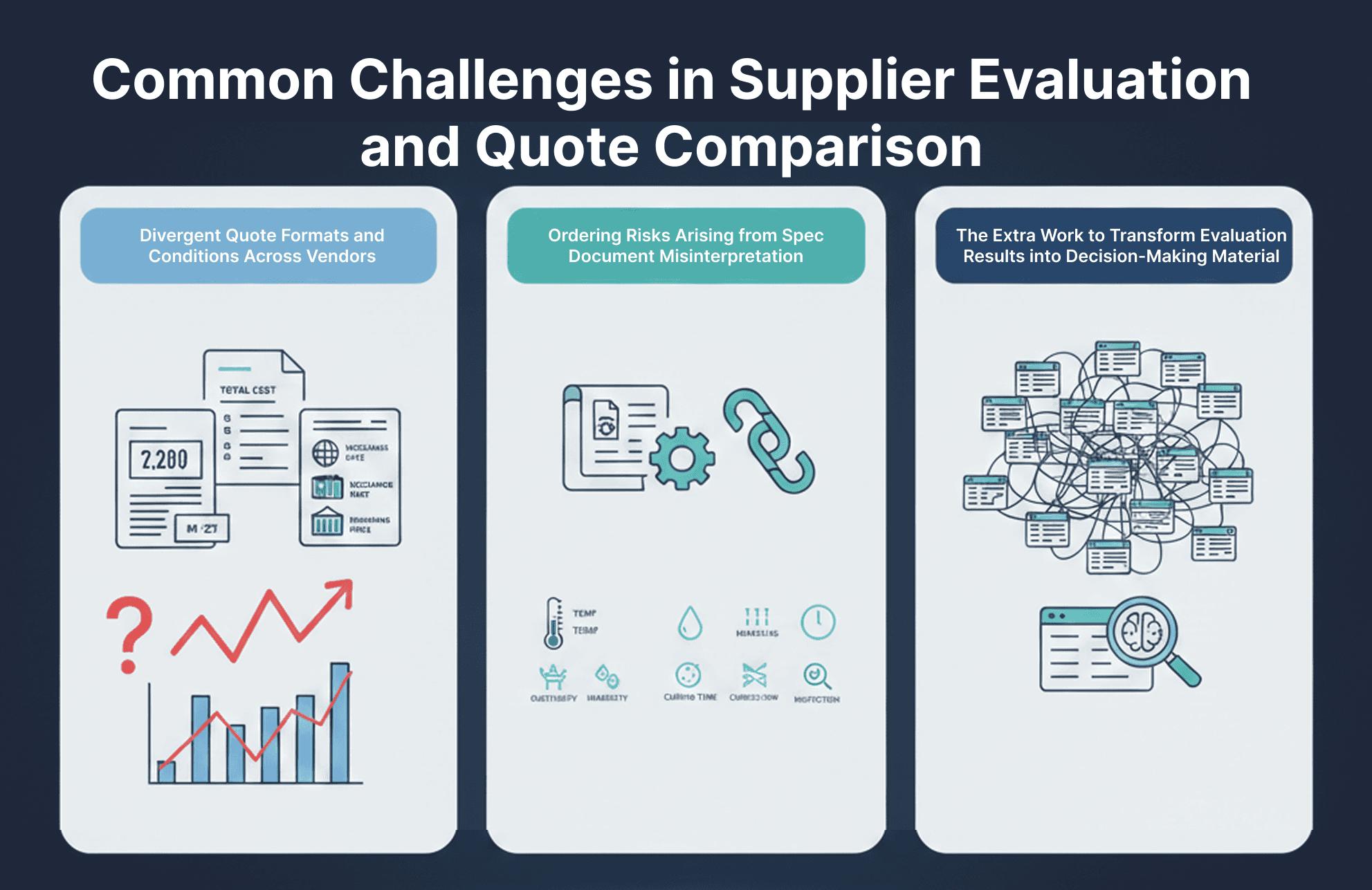

Common Challenges in Supplier Evaluation and Quote Comparison

2-1. Divergent Quote Formats and Conditions Across Vendors

Some suppliers provide total or lump-sum prices, while others itemize unit costs and ancillary charges. Failure to uniformly interpret boundary conditions—such as inclusion of shipping/insurance/duties, exchange rates, validity periods, or price adjustment clauses—can distort true cost comparison.

2-2. Ordering Risks Arising from Spec Document Misinterpretation

Even slight discrepancies in drawing dimensions/tolerances, raw material grades, process conditions (temperature, humidity, curing time), or inspection standards can lead to conformity issues after delivery. Different "languages" in specs can lead to varying interpretations of the same meaning, and these subtle misunderstandings can simultaneously impact quality, delivery, and cost.

2-3. The Extra Work to Transform Evaluation Results into Decision-Making Material

More challenging than the comparison itself is summarizing for reporting. Decision-makers want a one-page overview of "why this vendor," but the underlying data is scattered across dozens of sheets. Connecting evidence, assumptions, risks, and conditional approvals into a cohesive narrative consumes significant time.

Limitations of Existing Procurement Processes

3-1. Error Potential from Excel & Manual Comparison

While VLOOKUP/INDEX-MATCH/Pivots are powerful, a single breakdown in source integrity, unit conversion, or version synchronization can lead to results that appear correct but are fundamentally flawed.

3-2. Inconsistency in Qualitative & Quantitative Evaluation Criteria

Qualitative indicators like price, delivery, quality, and cooperativeness can be interpreted differently depending on the manager, project, or timing. Even with an evaluation form, ambiguous definitions of weights and scales reduce comparability.

3-3. Increased Management Burden with More Collaborators

As the number of vendors, items, and regions grows, queries, revisions, and requests for evidence explode. Communication scattered across emails, messengers, and spreadsheets severely diminishes traceability.

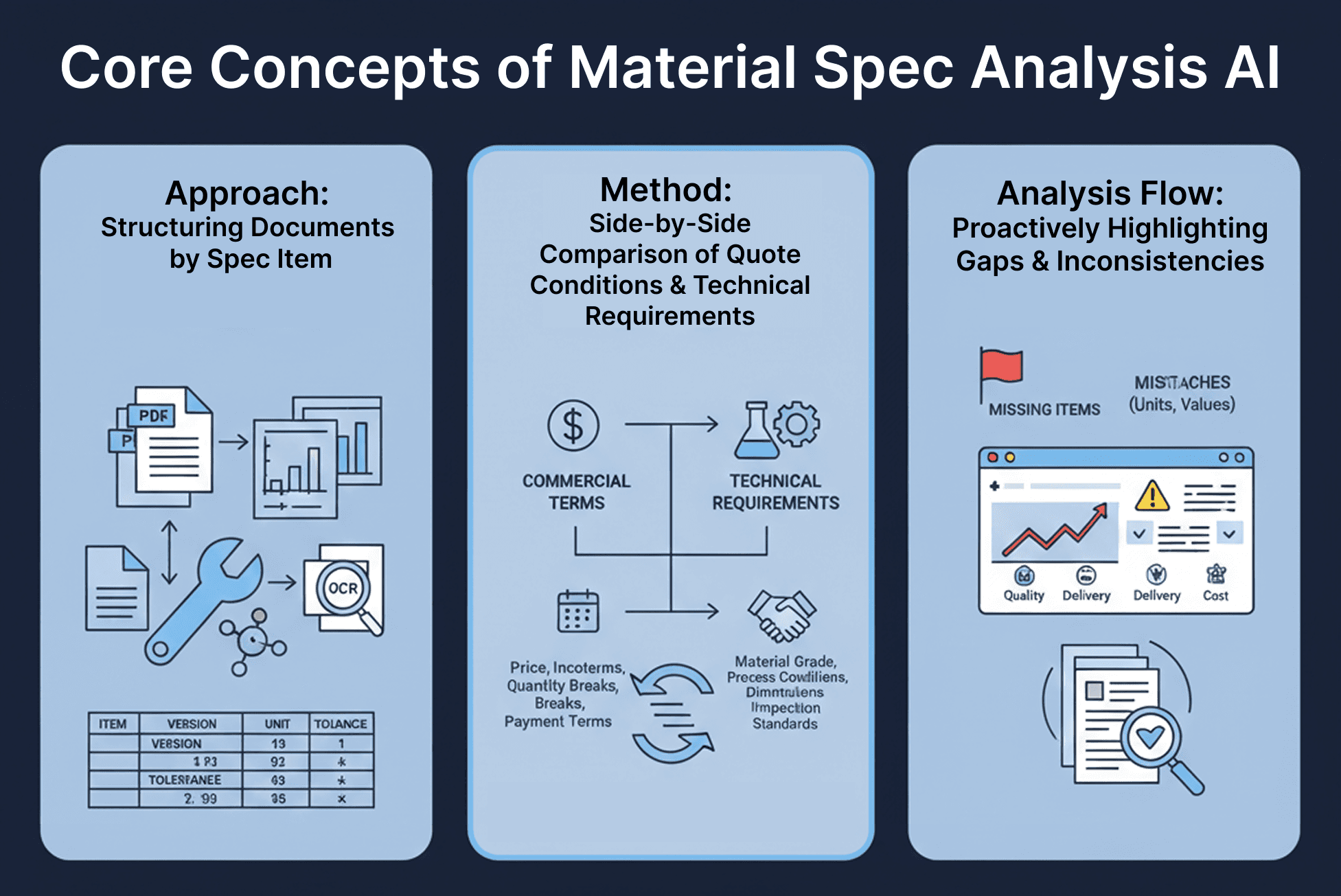

Core Concepts of Material Spec Analysis AI

4-1. Approach: Structuring Documents by Spec Item

Wissly parses PDFs, drawings, test reports, and specification sheets, breaking them down into meaningful units like dimensions, tolerances, materials, standards, process conditions, and inspection criteria. For scanned documents, OCR and layout analysis extract tables and captions.

4-2. Method: Side-by-Side Comparison of Quote Conditions & Technical Requirements

Commercial terms (price, delivery, logistics, warranty) and technical conditions (material, process, inspection) are aligned on a single screen. "Normalization" rules convert Incoterms, exchange rates, quantity breaks, and payment terms to a common standard. Technical requirement compliance is flagged as suitable, conditional, or unsuitable.

4-3. Analysis Flow: Proactively Highlighting Gaps & Inconsistencies

Wissly cross-references spec items with submitted documents, flagging missing items (not attached, not specified) and conflicting items (unit/value discrepancies, test standard mismatches) in a prominent queue. The impact on quality, delivery, and cost is scored, automatically recommending items for priority review.

Real-World Changes Brought by Automation

5-1. Structural Reduction in Supplier & Quote Comparison Time

Initial snapshot comparisons are reduced from hours to minutes. Even with revised quotes, automated conversion and sorting mean there's no need to start from scratch.

5-2. Prevention of Ordering/Quality Errors from Spec Discrepancies

An automated pre-order conformity checklist prevents minor discrepancies from escalating into post-shipment issues. The impact of alternative proposals (performance, cost, delivery) can be reviewed on a single page, accelerating decision-making.

Automated Supplier Evaluation Flow with Wissly.ai

6-1. Unifying Multiple Quotes and Spec Documents Simultaneously

Wissly parses RFQ responses, attached specs, drawings, and test reports in bulk, loading them into a standard schema. It automatically generates comparison tables by grouping spec items, vendors, and versions, marking missing, conflicting, or duplicate entries with quality badges.

6-2. Structure for Summarizing Results While Maintaining Fair Comparison Standards

Wissly instantly navigates thousands of scattered files to find critical clauses like Incoterms, exchange rates, quantity breaks, MOQ, and lead times. It automatically converts diverse document formats to a common standard, calculating weighted scores for price, delivery, quality, and risk in seconds.

6-3. Evaluation Deliverables for Procurement, Sourcing, and Quality Teams Alike

Executives receive one-page summaries, procurement teams see detailed commercial terms, and quality teams review technical conformity, test items, and risk logs. All views are linked to source snippets and file links, simplifying re-verification and audit responses.

Practical Application Scenarios

7-1. Automated Quote & Spec Comparison for New Supplier Selection

When selecting new suppliers, there's no need to manually cross-reference diverse quote and spec documents from 5-10+ vendors. Wissly instantly normalizes all response data to a common standard, generating an easy-to-read comparison table.

7-2. Organizing and Summarizing Regular Supplier Evaluation Data

Wissly automatically compiles delivery compliance rates, quality defect rates, and cooperativeness indicators on a quarterly or semi-annual basis to generate vendor performance reports. Trends, reasons, and improvement plans are linked, providing clear evidence for contract renewals, penalties, or improvement requests.

7-3. Pre-Order Spec Verification to Eliminate Potential Errors

Before issuing a PO, Wissly automatically performs a final conformity check on specs, drawings, and test standards to prevent omissions and inconsistencies. Change histories and approval chains are recorded, enhancing responsiveness to disputes and claims.

Reduce Ordering Errors Through 'Organization Method,' Not 'Review Time'

8-1. Faster Comparison Leads to More Accurate Procurement

Automating comparison, organization, and reporting not only reduces review time but also enhances decision quality. Standardized criteria and traceable evidence simultaneously boost negotiation power and internal trust.

Wissly offers robust on-premise/hybrid security, eliminating concerns about sensitive internal data leakage. It supports scanned document (OCR) and multi-language parsing, delivering verifiable source links and full change logs. Start automating your complex document tasks with Wissly today and elevate the value of your decisions!

Recommended Content