Insight

AI-Powered Technical Document Analysis for Manufacturers: Implementation Checklist

Dec 2, 2025

Why Automate Technical Document Review?

Manual Review Limitations in Massive Design and Specification Documents

Manufacturing companies produce and manage tens to hundreds of pages of technical documentation per product. These include design drawings, specifications, BOMs (Bill of Materials), quality standards, and test reports, existing in formats such as PDF, scanned images, and CAD drawings. The traditional manual approach to reviewing these documents is time-consuming, error-prone, and makes it difficult to apply consistent quality standards. Frequent design changes during product development also make it difficult to track and share document versions in real time. As technical documentation becomes more complex, the analog-centric review process reaches its limit.

The Need to Detect "Risk Signals" for Quality and Process Improvement

Many quality incidents in manufacturing originate from seemingly minor document issues such as inconsistencies, omissions, or unapproved specifications. For example, mismatches between designated and actual materials, exceeding dimensional tolerances, or using unapproved drawings can trigger failures. These are difficult for humans to catch, especially when multiple document versions or teams are involved. There is a growing need for AI-driven solutions that not only store documents, but interpret content and flag potential risks in advance.

How AI-Based Technical Document Analysis Works

Automatic Extraction of Specifications, Dimensions, Materials

AI systems extract key data such as specifications, material information, dimensions, and tolerances from text, tables, and drawings. For instance, a line reading "Ø25.4 ±0.1mm, material: SUS304" is parsed into structured data: diameter (25.4), tolerance (±0.1), unit (mm), material (SUS304). Key technologies include OCR (Optical Character Recognition), layout parsing, and context-based entity extraction. This structured data can then be used for comparison, validation, and reporting.

Detection of Non-Compliance and Risk Highlighting

The extracted data is compared to predefined standard references, such as internal quality guidelines or customer specifications. AI checks whether values are within tolerance and identifies missing or conflicting entries. Non-compliant items are automatically flagged with risk indicators in the document interface. This reduces the likelihood of oversight by human reviewers and proactively prevents quality issues.

Automated Version Comparison Between Document Revisions

Frequent design changes in manufacturing require careful management of document revisions. AI compares different versions of the same document at the sentence, value, table, and drawing element levels. It generates a change summary report with visual highlights of all modified sections. Features include before-and-after views, change history timelines, and version summaries to support design reviews and customer approval processes.

Benefits: Speed and Accuracy in Interpreting Technical Documents

Faster Review Time and Improved Error Detection

Reviewing a technical document can take from several minutes to hours manually. With AI, even multi-hundred-page documents are analyzed within minutes, with key items summarized in structured reports. This reduces review lead time and increases the accuracy of detecting subtle or hidden errors based on quantitative rules, improving overall reliability and efficiency.

Standardized Insights for Cross-Department Collaboration

Design, quality, and manufacturing engineering teams often review the same documents from different perspectives. AI-generated analysis provides standardized insights such as lists of non-compliant specifications, summaries of design changes, and over-tolerance issues. This ensures all teams are aligned on key information and reduces communication errors due to inconsistent interpretations.

Proactive Process and Quality Improvements

Document analysis results can lead to tangible quality improvements. For instance, discrepancies between design intent and manufacturing setup can be corrected early, or frequently non-compliant items can be flagged and turned into training material. AI enables a proactive quality approach based on "Quality by Design" principles.

What Sets Ryntra’s Technical Document Analysis Apart

Local Processing Without Data Leakage

Ryntra’s solution runs locally on-premise or within the internal network—ideal for industries like defense, aerospace, semiconductors, and medical devices. It eliminates the risk of technology leakage. Additional features include access control, audit logs, and encryption for robust security.

Support for PDF, CAD Exports, and Image-Based Documents

Beyond text-based files, Ryntra can process PDFs exported from CAD systems, instruction manuals with embedded images, and multilingual content. With advanced OCR and multi-layer analysis, it accurately interprets dimensional lines, table captions, and scaled diagrams.

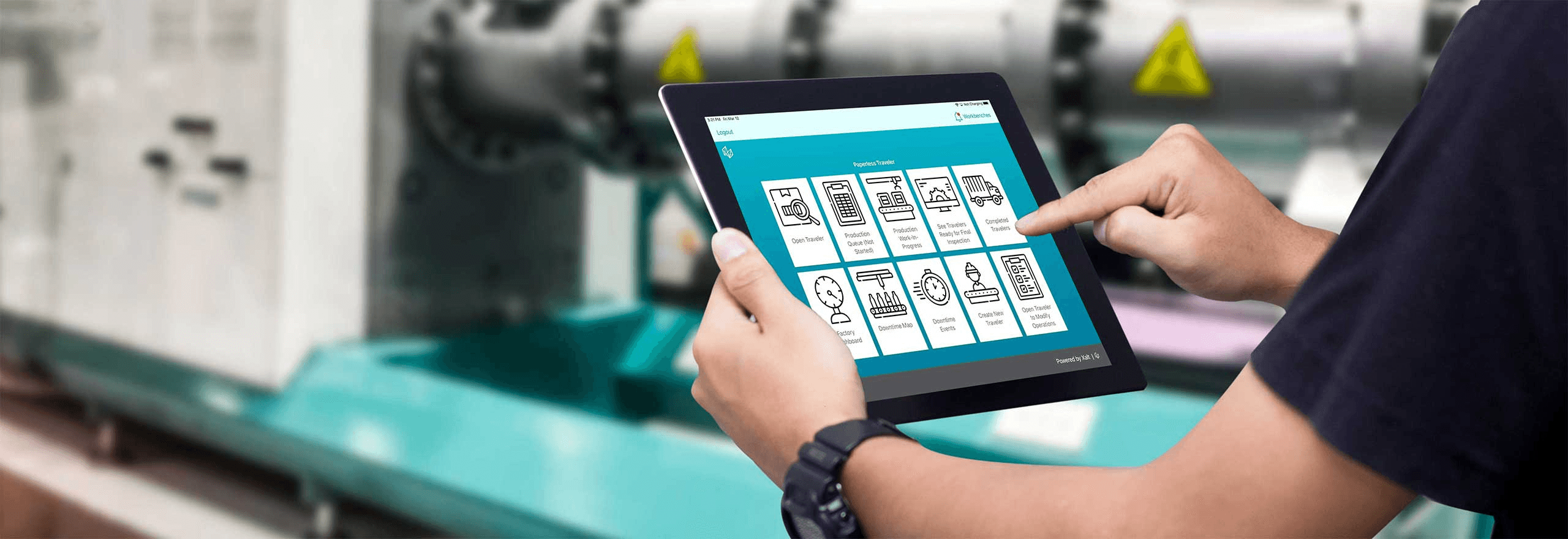

Integration with PLM and MES Systems

Ryntra's results are not just static reports—they can be integrated into PLM, MES, and ERP systems via API. For example, quality deviations can trigger alerts in the MES, or design changes can automatically be logged in the PLM. This integration streamlines workflows and maintains consistency across the manufacturing IT environment.

Pre-Implementation Checklist

Clean-Up and Structuring of Document Formats

Organizations must assess the types of documents they plan to analyze (PDFs, Excel sheets, scanned images, etc.). Improving OCR accuracy may require cleaning up resolution, font consistency, and drawing annotations.

Define Compliance Standards and Required Criteria

AI requires predefined standards for comparison—e.g., maximum tolerances, approved material lists, required annotation fields. These criteria also serve as training data for more accurate detection and reporting.

Map Results to Departments and Processes

Clearly define how each department will use the analysis results—e.g., for design review, quality audits, process setup, supplier document validation. This allows the automation scope to be tailored and scaled accordingly.

Practical Application Scenarios

Automated Design Change Review and Version Comparison Reports

AI identifies all differences between design documents and generates structured reports showing changes, affected parts, and revised values. This enhances traceability and speeds up design approval.

Automated Detection of Non-Compliance with Quality Standards

AI continuously compares document data with set standards and flags non-compliant items. The resulting risk reports support internal quality reviews and customer-facing documentation.

Automation of Work Instruction Management and Distribution

Ryntra manages updates to process manuals, SOPs, and inspection guides by versioning documents, notifying relevant teams, and ensuring consistent distribution. This eliminates gaps in communication and ensures teams operate with the latest information.

Conclusion: How to Extract Both Quality and Efficiency from Technical Documents

AI That Reduces Errors and Improves Communication

AI-powered analysis does more than read documents—it understands structure and context, extracting actionable insights for each department. This allows early detection of risk and clear, standardized communication based on original documentation.

Automating Technical Document Review with Ryntra

Ryntra delivers a technical document analysis solution tailored to the structure and workflows of real-world manufacturing environments. With strong security, high accuracy, and flexible customization, it enables rapid deployment and powerful outcomes. Transition your manual document review processes to intelligent automation today—with Ryntra as your partner in enhancing quality and productivity.

Anbefalet indhold